•

Jun 19

These forces aren’t operating in isolation; instead, they amplify and intensify one another, accelerating this shift toward reshoring and regionalized manufacturing. This approach, once hindered by higher costs, is now economically viable driving many to prioritize nearshoring and regional manufacturing.

Historically, offshore global manufacturing has prioritized cost efficiency by exploiting regions with lower labor and production expenses. This hyper-globalized approach, fueled by advancements in transportation, trade agreements and the widespread adoption of just-in-time supply chains, enabled companies to maximize their profit margins.

However efficient it seemed, this model often introduced complex dependencies and vulnerabilities, leaving businesses exposed to risks such as geopolitical tensions, supply chain disruptions and fluctuating tariffs. An environment of unpredictability further diminishes the ability to plan effectively for the long term, adding pressure on companies to adapt quickly and minimize risks.

No doubt, higher tariffs are the catalyst that is pushing manufacturers to reassess supply chain strategies. However, the intersection of rising tariffs and artificial intelligence in manufacturing is redefining the way companies operate on a global scale by reducing the benefit differential between nearshore vs. offshore manufacturing.

It is no longer just a logistical challenge, but a strategic imperative to regionalize manufacturing, building resilient and agile operations that can withstand geopolitical and economic shifts. In this environment, coupled with AI, onshoring has become more stable than offshoring.

Companies that bring manufacturing closer to their end markets mitigate tariff risks, maintain cost control, and improve adaptability and resilience in a volatile trade environment. In addition to cost reductions, AI and automation enhance operational efficiency, shorten lead times and are more responsive to market demands. Essentially, the regional model mitigates financial uncertainties and improves control over the supply chain.

Diversification and strategic sourcing have become equally critical, as businesses recognize the dangers of over-reliance on a single country or region for crucial components. By spreading operations across multiple locations, organizations can better safeguard against disruptions and enhance overall resilience. This strategic realignment protects companies from trade disruptions and positions them to thrive in a rapidly changing economic landscape.

Tariffs are incentivising companies to alter the global manufacturing landscape, compelling companies across various industries to regionalize their supply chains to mitigate costs and risks. For instance, Foxconn, an international electronics manufacturer, announced it will build a factory in Guadalajara, Mexico, to assemble chips for Nvidia. The automotive sector has undergone significant adjustments, as firms such as Toyota and General Motors restructure their North American supply chains to comply with shifting trade policies under the United States-Mexico-Canada Agreement (USMCA).

In addition to these changes, the COVID-19 pandemic highlighted vulnerabilities in global supply chains, particularly in critical industries such as healthcare and semiconductors, where production delays resulted in widespread disruptions. Together, these case studies illustrate how tariffs, combined with global uncertainties, are driving a trend toward regionalization, ultimately reshaping the strategic priorities of major manufacturers worldwide.

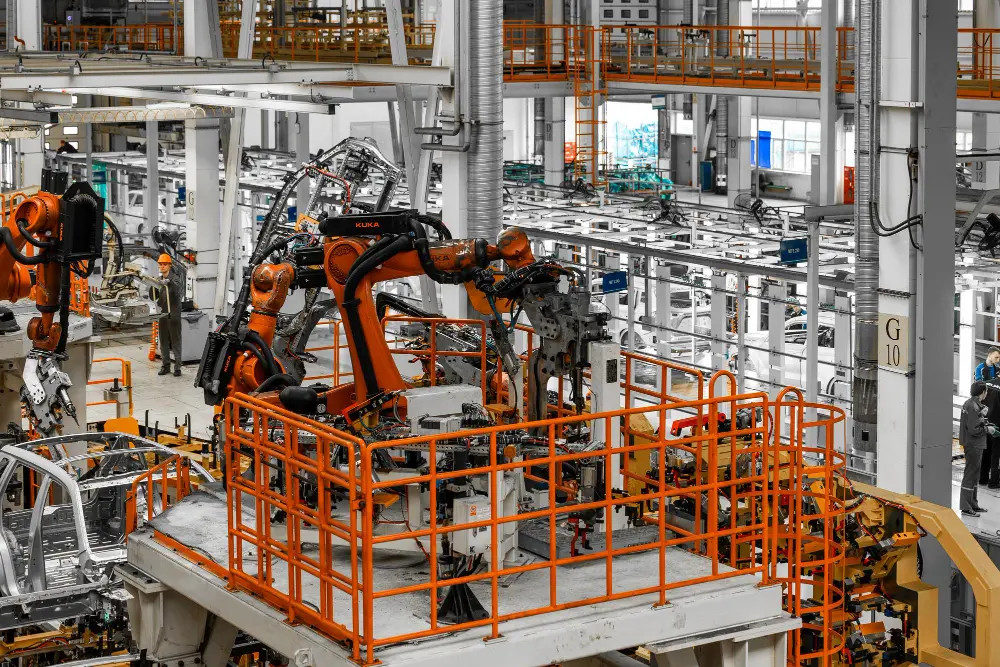

The acceleration of AI and automation that is driving the regionalization of manufacturing enables high-cost countries to compete effectively on a global scale. Through automation and robotics, AI reduces reliance on low-cost labor.

AI also powers maintenance and quality by analyzing machine data to foresee potential failures, ensuring minimal downtime and optimized production schedules. Additionally, advanced vision systems equipped with AI enable unparalleled quality control, identify defects faster and more accurately while reducing waste. These AI innovations unlock new levels of productivity and competitiveness for manufacturers worldwide, key catalysts for the regionalization movement.

Traditional manufacturing factories transform into smart, efficient ecosystems through the revolutionary impact of AI and automation. With the integration of IoT and sensors, systems are now seamlessly connected, generating vast amounts of data that enable intelligent decision-making in real-time. This extensive network enables manufacturers to monitor performance, identify inefficiencies and automate instant and precise adjustments. AI algorithms elevate production planning to the next level, optimizing workflows, managing inventory and responding swiftly to fluctuating demands.

Beyond the factory floor, AI plays a pivotal role in supply chain optimization by delivering accurate demand forecasting, streamlining logistics and mitigating risks across regionalized networks. As regionalization reshapes global manufacturing, AI ensures businesses can adapt with agility and precision.

AI is reinventing product design and innovation, providing manufacturers with unprecedented tools. Through generative design, AI empowers engineers to create and optimize product designs or prototypes with speed and precision previously unimaginable. By analyzing numerous design permutations, AI can streamline prototyping and identify the most efficient and cost-effective solutions, thereby reducing time-to-market and production costs.

Additionally, advancements in AI are making mass customization and personalization more accessible. Manufacturers can now efficiently produce highly individualized products that cater to specific customer preferences without compromising scalability. This shift not only enhances customer satisfaction but also provides companies with a competitive edge.

Regionalizing manufacturing has far-reaching economic and societal implications. A stronger domestic manufacturing base enhances economic resilience, providing a buffer against global supply chain disruptions, currency fluctuations and economic shocks. This shift reduces dependency on distant markets, empowering nations to maintain economic stability during times of crisis.

Additionally, regional manufacturing hubs can foster dynamic innovation ecosystems. By clustering industries, talent and resources around these hubs, businesses can accelerate technological advancements and stimulate local economic growth. From an environmental perspective, shorter supply chains reduce transportation emissions, contributing to a smaller carbon footprint.

The trend toward regional manufacturing, which began to supplant global manufacturing, started long before the focus on tariffs and taxes. However, the recent emphasis on tariffs, coupled with the advancements in technology, provided an immediate financial incentive to address the issue. Businesses that adopt AI and automation will find it easier to adapt to regionalized manufacturing. Together, these dynamics are reshaping the manufacturing landscape, creating opportunities for organizations that are ready to adapt, innovate and regain control of their supply chains.

Other articles that may interest you